Aluminum Composite Insulation Panel

Aluminum Composite Insulation Panel: A Versatile Building Material

Introduction

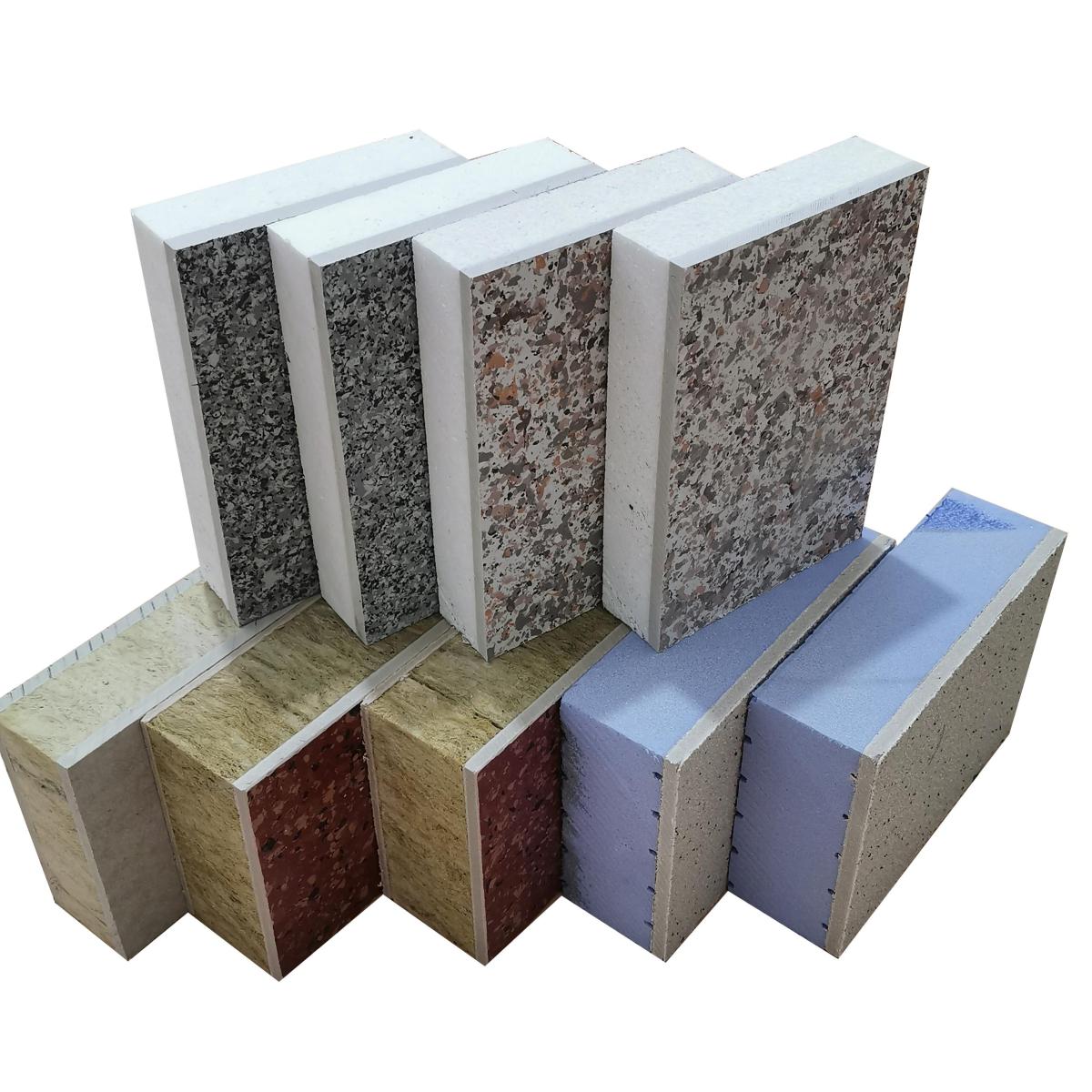

Aluminum Composite Insulation Panel, also known as sandwich panels, are prefabricated structural elements used in various construction applications. They consist of a core material sandwiched between two outer metal sheets, creating a lightweight yet strong and thermally efficient component. This combination of properties makes them a popular choice for modern buildings.

Features

Aluminum Composite Insulation Panel possess several key characteristics that contribute to their widespread use:

- Thermal Insulation: The core material, typically made of foam like polyurethane (PUR), polyisocyanurate (PIR), or mineral wool, provides excellent thermal insulation. This reduces heat transfer, leading to energy savings and improved indoor comfort. The specific thermal performance is determined by the core material's properties and the panel's thickness.

- Structural Strength: The metal outer sheets, usually aluminum, provide structural rigidity and strength to the panel. This allows for large spans and reduces the need for extensive supporting structures.

- Lightweight: Compared to traditional building materials like concrete or brick, insulated panels are relatively lightweight. This simplifies transportation, handling, and installation, resulting in faster construction times and reduced labor costs.

- Fast Installation: The prefabricated nature of Aluminum Composite Insulation Panel allows for quick and easy installation. They are manufactured to precise dimensions and simply connect together, significantly reducing on-site construction time.

- Durability and Weather Resistance: The metal outer sheets protect the core material from the elements, ensuring long-term durability and resistance to weathering, corrosion, and other environmental factors. Specific coatings can further enhance this protection.

- Fire Resistance (depending on core material): Some core materials, like mineral wool, offer excellent fire resistance, making them suitable for applications where fire safety is a critical concern. Others offer varying degrees of fire retardancy.

Applications

The versatility of Aluminum Composite Insulation Panel makes them suitable for a wide range of applications in various industries:

- Walls and Roofing: Aluminum Composite Insulation Panel are commonly used for external walls and roofing in commercial, industrial, and residential buildings. They provide excellent thermal insulation and weather protection, contributing to energy efficiency and occupant comfort.

- Cold Storage: Their superior insulating properties make them ideal for constructing cold storage facilities, refrigerated warehouses, and food processing plants, maintaining the required low temperatures.

- Cleanrooms: Aluminum Composite Insulation Panel are used in cleanrooms and laboratories where strict hygiene and environmental control are essential. Their smooth surfaces and airtight seals help maintain a sterile environment.

- Industrial Buildings: Factories, warehouses, and other industrial structures often utilize Aluminum Composite Insulation Panel for their speed of construction, thermal performance, and cost-effectiveness.

- Agricultural Buildings: They are also used in agricultural buildings like barns and poultry houses, providing insulation and protection for livestock and crops.

- Modular Construction: Aluminum Composite Insulation Panel are increasingly used in modular construction, where entire building sections are prefabricated off-site and then assembled on location. This approach offers faster construction times and greater quality control.

- Interior Partitions and Ceilings: Beyond exterior applications, Aluminum Composite Insulation Panel can be used for interior partitions and ceilings, providing thermal and acoustic insulation and creating flexible spaces.